Triumph-engined, Greeves-framed specials have become a marque in their own right, but that’s not to say when building one you have to follow any rules.

Words: PHIL TURNER Photographs: GARY CHAPMAN

Special building has all but disappeared from the modern motorcycling world; the design and complexity of new machines rendering cross-pollination between marques and models nigh-on impossible. The last bastion of the pursuit are high-end custom houses, building expensive, bespoke machines, destined only for display or the private collections of the few who can afford them.

Enjoy more Classic MotorCycle reading in the monthly magazine.

Click here to subscribe & save.

The builders of yesteryear, who took to their own sheds and workshops for reasons of competitive edge, or simply for the sake of it, will sadly soon be relegated to annals of history. You don’t have to look too far in the classic world, though, to still see a chink of light breaking through; the art kept alive by a handful of enthusiasts for the ‘shed build’.

Engineering mind

One such practitioner of the special is Chris Sawyer. Readers may remember I took a turn on Chris’s Cotton in the April 2023 issue, which, although at a glance appears ‘standard’, to the more knowledgeable it bears the hallmarks of an owner who doesn’t shy away from modifying their machine to make it their own. Chris is at a bit of an advantage in that regard, as he possesses that rare commodity of a real engineering mind: knowing that something should or could be improved; possessing the thinking processes to work out how; and the skill, patience and determination to make it happen. It’s an expertise he discovered early in life, as he explained:

“I had a very boring apprenticeship in the plastics industry at ICI. I ended up in the drawing office and I could see my future panning out in front of me; 40 years-on, talking about gardening and caravanning holidays. I remember thinking to myself: ‘I need to get out of this, this is terrible!’

“So, off I went back to college; a four-year course in engineering at Hatfield Polytechnic. I taught myself to mend cars to make a bit of extra money. That got me interested in vehicle design, and I realised what I wanted to do.”

Big trucks

With qualifications in hand, Chris set about finding employment. Pragmatism would lead him down an unusual path, but one that would turn into a lifelong passion: “I realised I couldn’t design cars for Formula 1, so I went to the other extreme: to Scammell in Watford.

“For me, it was just the best place in the world. If you imagine being paid to ride motorbikes around all day, being paid to play with big trucks was like that for me. I stayed there 15 years, until it folded.”

On leaving Scammell, Chris’s career took a few twists and turns, but all the time keeping him firmly rooted in his passion for engineering: “After Scammell, I worked for a company making recovery vehicles.

“Then I set up on my own, freelancing. I liked working by myself and for myself, I learnt that from working on cars.

“It was wonderful. I worked on all sorts: commercials, trailers and body building; all sorts of things related to my previous experience. I’ve never let the fact I’ve never done it before stand in my way!

“I had a little company making things to do with inflating and deflating tyres on off-road vehicles; I actually held a patent on one of those things. I did a lot of expert witness work in court cases, which was sterile but paid the bills, but, mainly, freelance design work, civilian and military, design was always the thing. Eventually I forced myself to retire because it meant I could do more with my own bikes.”

Successful combination

It was pretty much a foregone conclusion that when Chris fancied a bit of green laning he wouldn’t settle for an off-the-shelf machine – though he did tell me he had a BMW G650 X-Country at one stage, but that wasn’t quite serving the purpose – or was it just that you couldn’t fiddle with it as much as you’d have liked, Chris?

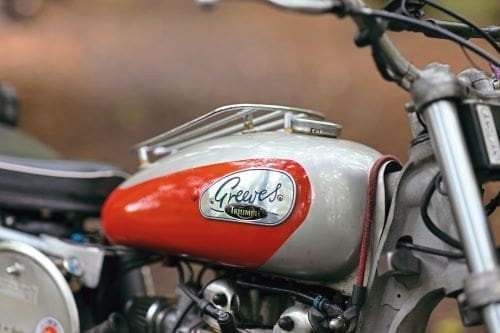

The question of what to go for was easily answered by one of, if not the most popular of all off-road specials: the Tri-Greeves. For those unfamiliar with the specials, Greeves trials bikes and scramblers were some of the most competitive of their day, but although their chassis was widely recognised as among the best, there were many riders unwilling to put up with the trying temperament – and lack of torque – from the chosen two-stroke engines. The natural solution was to fit a four-stroke in their place and Triumph’s compact, smaller unit-construction (350 and 500cc) twins were a relatively easy fit, and became one of the most popular choices. The combination was so successful, and the conversions so numerous, that the Tri-Greeves has almost become a recognised marque in its own right.

Bit of a polish

Chris’s bike marries a 1961 3TA engine with a 1965 Anglian trials bike frame, the latter originally hailing from the Isle of Man, as Chris explained: “It was bought new on the Island, Salisbury Garage I think it was. It then came over to the UK and went through various incarnations. I bought it as a rolling frame about 10 years ago.

“I actually have another Tri-Greeves that I’ve spent a lot of time and money on and I thought, well, I don’t really want that one to get all battered and muddy. I already had the engine. It was actually originally in the other bike, until someone persuaded me to fit a 500. I also had a load of bits that I’d made for the first bike, and then discarded. I thought if I could find another frame, all I’d really need is a set of forks and I could have another complete bike. I came across this one and it had the Cerianis already on it; they were a factory option I think.”

The frame, although complete and structurally sound, was showing signs of a life well lived, as Chris explains: “It had been used for trials, so it was all chipped and knocked about. I decided to get it shot blasted. The light grey, according to the experts, was a Greeves colour. It’s not a very practical colour, but I’m not a great washer and polisher, as you can see. Petrol tanks might get a bit of a polish, but there’s other things in life to do, you know?”

Lining up chains

Walking me round the Tri-Greeves, Chris explained how fitting the unit-construction 3TA engine into the Anglian frame was relatively straightforward: “In the factory, you would go to Villiers or whoever and they would give you a drawing of the engine with all the mounting holes, so you can lay it all out and design the frame around it. Without that it’s a little more difficult, so you have to do a lot of jiggling about and seeing where things fit.

“Saying that, there was no modification needed to the Anglian frame. These Triumph engines, you put them in and there’s not a quarter of an inch of movement, it’s like they belong there. It has to be slightly offset, but you just have to make plates up and get the chains in line. That’s really what specials are all about, lining up chains.”

Sorting the exhaust wasn’t quite as straightforward, partly down to what Chris wanted: “That’s the thing people first notice. There are various ways of arranging the two pipes on these specials.

The obvious way is to have two separate pipes of course, but I wanted the Siamese system to be able to use this (modified) original silencer. You can’t bend round-profile pipes that tightly, and as Greeves themselves did it once with square welded sections, so that’s what I did.

It took forever. It was all done on the drawing board first, then transferred to paper, then to cardboard and then to metal. I had a spare cylinder head so I could put it on the bench and take measurements off it, which helped.”

That was the front part, the rest of the pipe was mocked up and tack-welded by Chris then the finished piece you see here made in stainless, Chris adding: “They were chromed on the Anglian, but I wasn’t too keen on that.”

Making things out of rod

The longer I looked at Chris’s Tri-Greeves, the more my untrained eyes started to see more and more components and additions, that all represent a solution to a problem, or a practical touch added on: “There’s all sorts of odds and sods on it that I’ve made.

“I actually made the sidestand myself. They’re much more difficult to design than you might think. They can’t go too much or too little forwards or sideways, and if you get them wrong… That’s about the Mark 10 version that’s on there! The rack is kind of interesting because it hides a D-lock underneath it. That means I’ve got a little bit of security.”

And that gear lever? I ask Chris as we circle the bike: “Yeah, that’s kind of my thing, making things out of rod. All the materials are far away from the neutral axis and there’s just fresh air in the middle, with something to stabilise it. They’re quite easy to make and just look different.”

Now, I’ll freely admit to being no expert in Tri-Greeves’ or Greeves, but even still as we continued round Chris’s bike I was beginning to feel slightly inadequate for not being able to spot the non-standard parts. Perhaps sensing it, Chris put me at ease: “People who are special builders, they spot things that regular motorcyclists don’t. Regular riders just don’t see all the homemade bits, and even when they do, they don’t realise they sometimes take days and days to make, and that half the time they don’t work, or you have to do them four times. If you get fed up after the first time, specials are definitely not your game.”

Not invented here

If you read the Cotton piece, you might remember that all the parts he makes for his bikes start life on the drawing board. It’s the way he was taught and the way he still prefers to work: “Some people are good at just looking at things and saying: ‘well, I’ll cut a bit off here and maybe a bit there’ but I find it harder to visualise. I have to draw it and then I know it’s right.

Like the oil tank, I made that myself. I drew that mainly just to fill in that triangle in the frame. It had a Tiger Cub one on it, which was almost round and it just didn’t look quite right to me. I’d never done an oil tank before, so it was a bit of a learning curve, but I’m happy with how it turned out.

“I spend a lot of time walking around looking at other people’s bikes, spotting things and thinking ‘that’s a great idea. I could do something like that.’ I’m not precious about using or adapting other people’s ideas. Engineers are often guilty of ‘not invented here’. I just admire other people’s ideas.

“That’s part of the pleasure for me. Certainly in the winter when it’s all cold and horrible, it’s quite nice to get in the office and draw something.”

Knees bent

The other part of the pleasure for Chris is of course riding the Tri-Greeves and that, he reports, is very enjoyable indeed: “It has turned out to be my favourite bike, because it just does everything. I do a week touring in Wales in June, and I go to the Isle of Man. I go for rides with like-minded friends in my local club, and with my next-door neighbour on his modern Honda, the Greeves just does everything.

“Even with that silly little trials saddle, it’s comfortable. I can ride all day. The thing with a special is you can put the pedals and handlebars wherever you want, and really tailor the riding position. That’s why the gear change has gone down by six inches, because otherwise I’d be riding around with my knees bent right up all the time.”

Now, I’m built much closer to the ground than Chris, and with my diminutive frame I definitely had a bit of a stretch to the bars, but other than that the Tri-Greeves is indeed very, very comfortable.

It also feels surprisingly spritely to me. Chris billed it as being ‘mild,’ but I have to say opening the taps in second, third and fourth it pulled really well, and felt strong right through the rev range.

A whine in third

Chris has it set up more for road riding these days, as he explained: “The sprockets came off the other bike, so it’s quite low-geared, but it will happily sit on an A or B road. It’ll cruise at 50 and pull 60mph for overtaking, but you can change into top at 20 and it’ll pull away quite happily.

It’s got a brand-new Concentric Premium carburettor on it. It had a Monobloc on. I checked it on the Isle of Man and it was giving 90 to the gallon.”

I asked if it sees much off-road action: “That was the original idea with it, just to do a bit of green laning, but I just have to be a bit sensible now and stick to very gentle green lanes, B and A roads. I’m 73 now, and if I fall off in the woods or on a track, I could break a leg and never ride again. I want to be like the guys I know who’re still riding at 80-plus.

“One of the best things I did to the bike was to change the tyres from trials type to a mixed-use pattern. I’d been meaning to do this for years but struggled to find one for the unusual 19in rear wheel that Greeves used on the Anglian. Eventually, I found the Heidenau K60 Scout Dual Sports. Fitting tyres on a special can be a problem with clearances etc but Heidenau provide full technical data, unlike some other makes, and I do have a bit of a thing about tyres. These ones are excellent, really confidence inspiring.”

And the next iteration? “Well, really not much. It’s got a bit of a whine in third gear, which you might have heard on the road. It would be nice to sort it out as third and top are close and you use third a lot in places like Wales. However, I’ve lived with it for years and frankly I find engine work and maintenance is a necessary chore that has to be done. Designing and making new bits is much more interesting. Since the test, I’ve just upgraded the lights by adding a different pair of spotlights with new brackets and added a new digital speedo which lights at night.

“I don’t think I’m going to do much more than that really, but I’ll come across something to do, y’know…”

I have no doubt you will, Chris.

Advert

Enjoy more The Classic MotorCycle reading in the monthly magazine. Click here to subscribe.

Enjoy more The Classic MotorCycle reading in the monthly magazine. Click here to subscribe.